Prioritised:

Immediate:

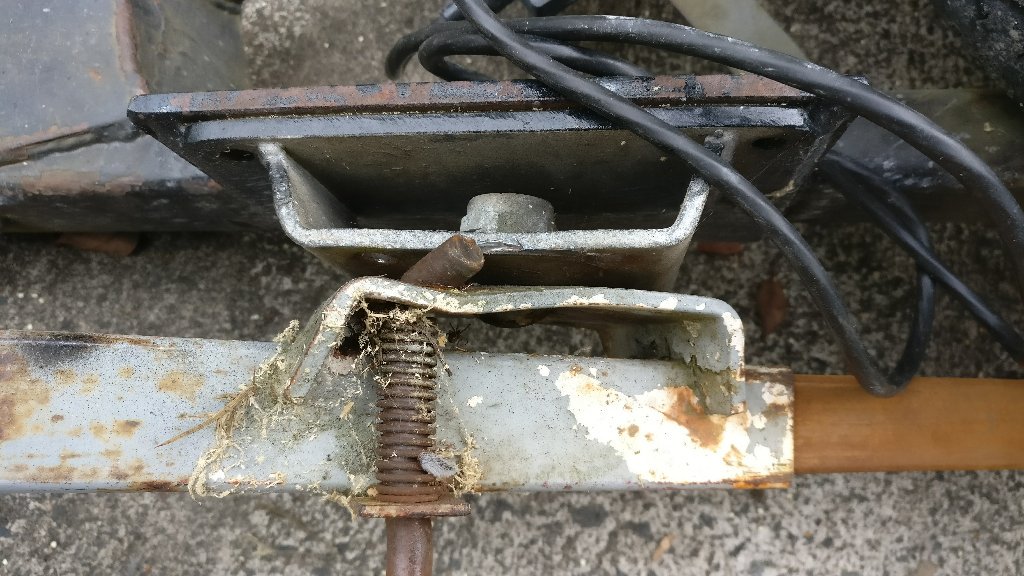

- Jockey wheel mechanism: Fix damage to hinge/lock

- Chain connection point: Replace 3mm plate with 6mm plate

- Hitch mechanism: Replace s/s fasteners with grade 10 cap screws and nylock

- Safety pin setup: New better pin with spring loading

- Jockey wheel mechanism: Lighten over-built bracketry

- Spare tyre: Remove from draw bar and fit beneath rear of deck (balance improvement)

- Front/rear gates: Rebuild with stronger construction for heavy timber loads

- Front/rear gates: Add more hinge points for increased strength/load capability

- Guards: Triangulate towards extremes with foot holds for climing up safely

- Deck: Reinforce centre 50x25 U beam that is under spec

- Deck: Replace working surface with new material, possibly hardwood or some laminate

- Sides: Add tie rail and running rail for carrying heavy wide things (eg my truck deck)