There are some preliminary designs in the works, I will post them here as soon as I can.

Feel free to share your thoughts on what should and shouldn't be on the board(s).

The most important ones are those that can be applied to any engine.

Anywhere from general ideas to fine details are ok.

Thank you in advance for your input.

The list (for the initial version) :

- General

- Sandwich construction

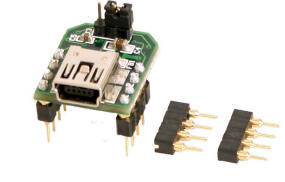

- FM Adapt board on top for upgradeable processor options

- Input board in the middle, 160mm x 100mm Eurocard form factor

- Output board below that, 160mm x 100mm Eurocard form factor

- Further boards can be added above and below the 3 base boards

- All 100 pins passed through every board

- Where space allows, prototyping areas on the main two boards, but this is not required as extra boards can be added to the sandwich with ease

- Power

- Separate battery feeds for MCU supply/sensor supply, High power devices, Battery reference (4)

- Separate grounds for signal/MCU/sensor/reference and High power devices (3)

- MCU supply VERY well filtered and protected

- Zener clamp/regulator at around 20V for MCU

- Reverse voltage protection diode and possibly fuse

- Series Diode for revers protection too (possibly not as the voltage loss may be intolerable)

- Fused heavy power and ground lines (large values for reliability)

- Reverse voltage and clamping/clean up on the heavy power and ground feeds too.

- Independent filter return pins for these

- High power series resistor that can stomach 15V continuously for the previous two features.

- Good sized reservoir capacitor to supply the MCU during low transients

- Sensor 5v reference voltage using own self protected regulator

- MCU LDO regulator on processor board

- Input board features

- 1 or 2 layer only (easily printable at home)

- At least 50 built in input conditioning circuits total

- Sensitive inputs at same end of the board as the MCU

- Multiple VR sensor inputs provisioned (discrete or integrated) : 3x engine, 4x wheel, 1x drive shaft, ???

- All 16 ADC channels provided with multi configurable setup (input impedance resistor, series resistor, internal filter cap, external filter cap, ??)

- General digital IO filter circuits provided for most pins (same as or similar to ADC input circuits)

- Space for up to 4 MAP sensors (pre-intercooler, post-intercooler/pre-throttle, manifold/ports, altitude OR 4cyl multiplexed ITB use (chosen in software)

- All input pins clamped with 5V1 zeners

- All input pins reverse voltage protected with signal to ground reverse biased diode

- All input pins current limited with 1.6k resistors

- All input pins filtered at the CPU with a capacitor of application dependent size

- Pull up (5V) and/or downs (0V) provisioned for all MCU pins that do not have built in ones

- Output board features

- 1 or 2 layer only (easily printable at home)

- At least 50 built in output drive circuits total

- High current stuff positioned at the far end of the board from the MCU (and on the bottom side)

- Provision for 24 heat-sinked high current devices in to220 and/or DPAK form for driving injectors, coils, relays, solenoids, fans, pumps etc

- Provision for at least 50 to92 pre-driver transistors/FETs of a common pin out with triangle footprint (jumper out otherwise)

- As many as possible configured for high side OR low side use via jumpers

- Provision for optional P&H chips before the 6 injector drivers (jumper out otherwise)

- Provision for pull up or pull down for each pin by way of four pads in square layout for vertical resistor (0,5,12,Out)

- Provision for remote current sense resistor on at least the 6 injector outputs (jumper out otherwise)

- All output pins current limited with 1.6k resistors

- Add on compatibility features

- Headers provided for SCI/SPI/IIC/CAN etc for easy interface to boards as shown below

- ???