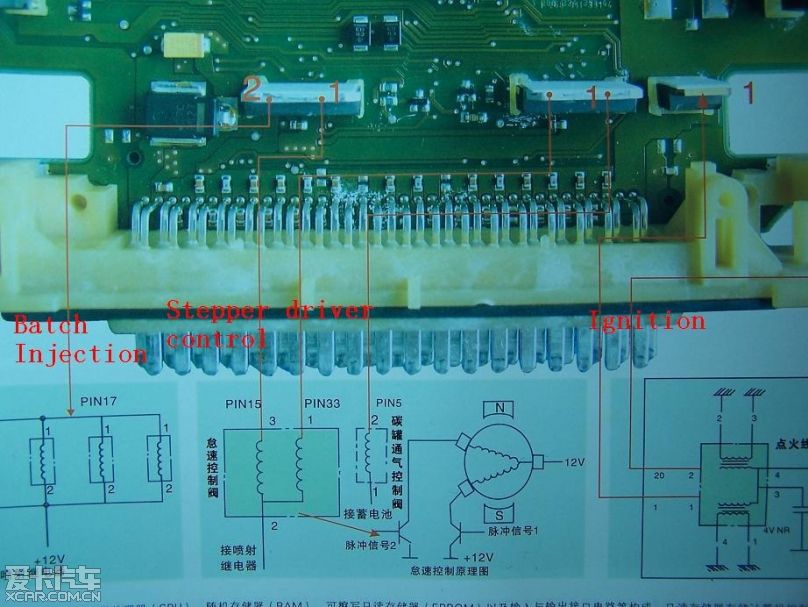

1 dash board tacheometer drive. PP5

1 pair of idle air valve drive. PP6&PP7

1 gas tank ventilation valve drive. PP3

I draw a diagram represent my GND designFred wrote: CPU, analogue should be one ground, but it comes in from the head/block/battery for the CPU and then goes out to the sensors from the ECU. ignition drive should share CPU ground IF it's low current. If it's high current, it should be isolated. Injector and low side ground(s) should be isolated.

What do you need an O2 sensor ground for? That worries me. That should typically have its own controller which grounds independently and just shares a signal line. Heater grounds for built in O2 stuff should be isolated.

Fred.