Hmm, 2 is the delta too high error value. It looks like the oldFred wrote:Sim, the sync loss during crank IS exactly what I said it was. With the fixed up OLV it's obvious

http://stuff.fredcooke.com/sync.loss.du ... rances.png

You get a "sync lost how" code for each loss, and this one was 2, and 2 is the time checking code.

IE, the numbers change will solve it, you can relax on the logging endeavour that I asked for in IRC. I'm 100% confident that it's this.

Fred.

Bosch starter can accelerate the crank faster than you expected.

I guess that's one part of the car I don't have to worry about

for a while.

I added some #ifdef blocks to open the window up to 500-2000 as

you suggested.

I went down and loaded the new build on the EMS and fired it up a

couple of times. The sync loss while cranking is gone, it fired up and

ran for several minutes with the sync loss value holding at zero

in MTX.

Looks like you were dead on Fred, good call!

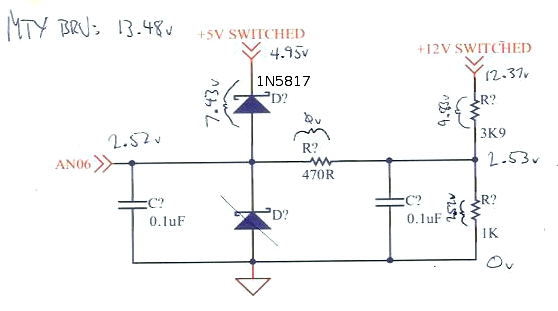

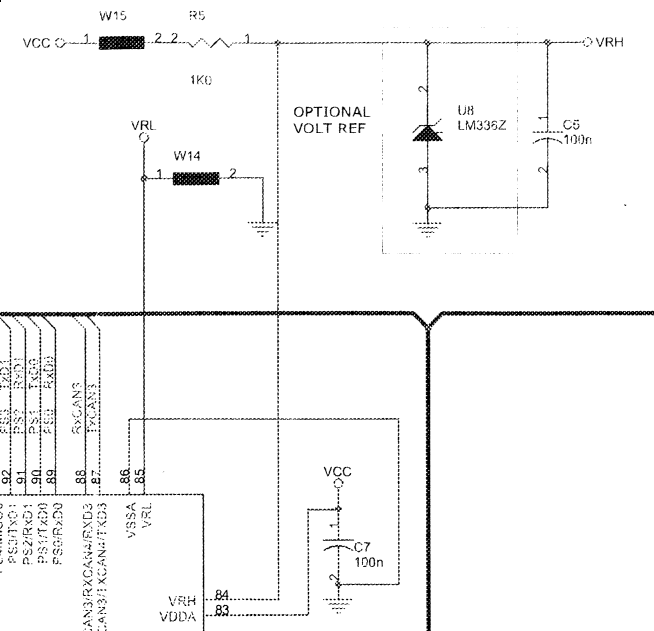

In other news, I built a BRV circuit today to measure the battery

voltage. I essentially copied the circuit from the RavAGE pdf

(thanks Dan!) I only had one Schottky diode left from the 5 pack

I bought for the MAP sensors (PN 1N5817), so I used it on the 5v

side on advice from Fred.

The BRV circuit works, but reads about 10% high. The MAP and AAP

sensors also read about 10% high. I suspect the Schottkys, but

I'm probably not qualified to speculate.

I also discovered that a GM temperature sensor threads into a

hole on the cylinder head. This will simplify the CHT install

greatly.

[edit] Oh, regarding the 24and1 wheel, I did clean it up a bit.

It had a little surface rust on it which I polished off, the

perils of mild steel, I guess. It was clean going in.

[re tuning]

I'm not looking to push the timing as far as I can, I want det

cans for safety, more than anything, and also to get a feel for

what an engine sounds like with an ear pressed up against the

block. My goals are pretty conservative.

sim