1. Lighter

2. Much longer life/higher cycle capacity

3. No self discharge

4. More stable voltage (old power locks/windows work better with engine off)

5. Incredible current to capacity rating depending on cells

6. Better starting performance due to stable voltage

7. No acid vapour to rust old cars

8. Safe in a collision/puncture/overvoltage/overheat/etc - will not explode (Lead Acid is mostly safe, but during charging has H2 gas floating around which can/will give you an acid bath if not careful)

And likely other things!

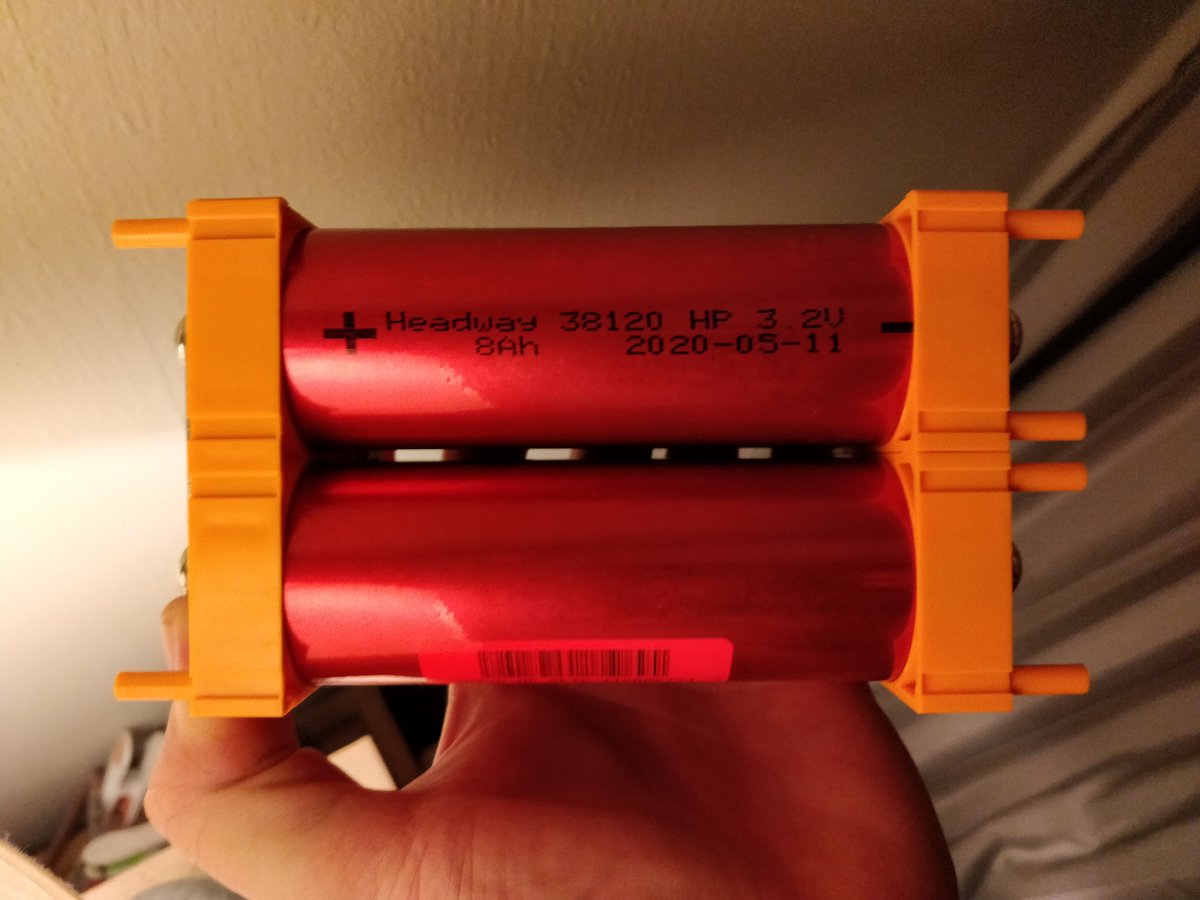

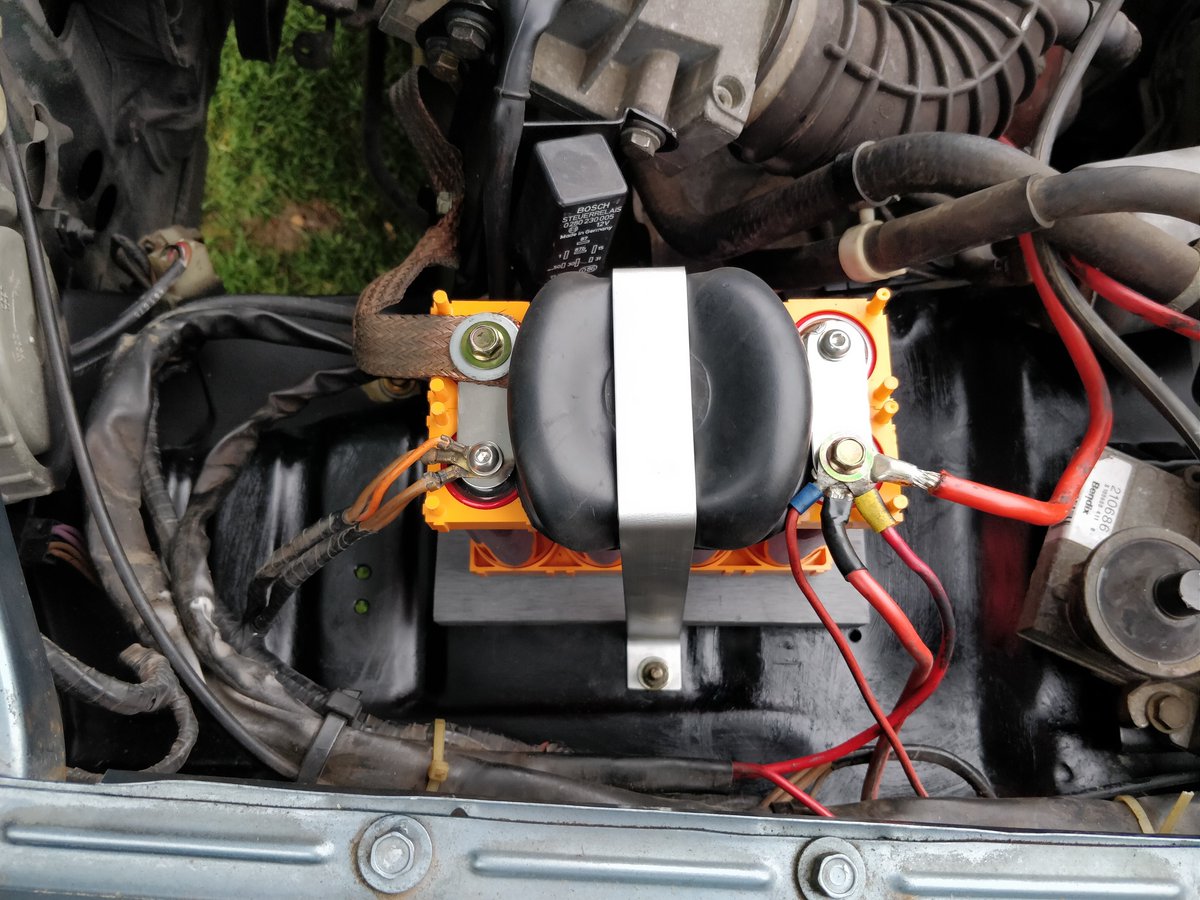

The cell of choice for me is the Headway 38120HP battery with:

- 8AH capacity

- 300A CCA dead short discharge

- 200A 30 second short term discharge

- 160A max continuous discharge

- 38x120mm cylinder form factor

- 3.2V nominal results in 12.8V nominal with any 4S series configuration

The systems I intend to use for these are as follows:

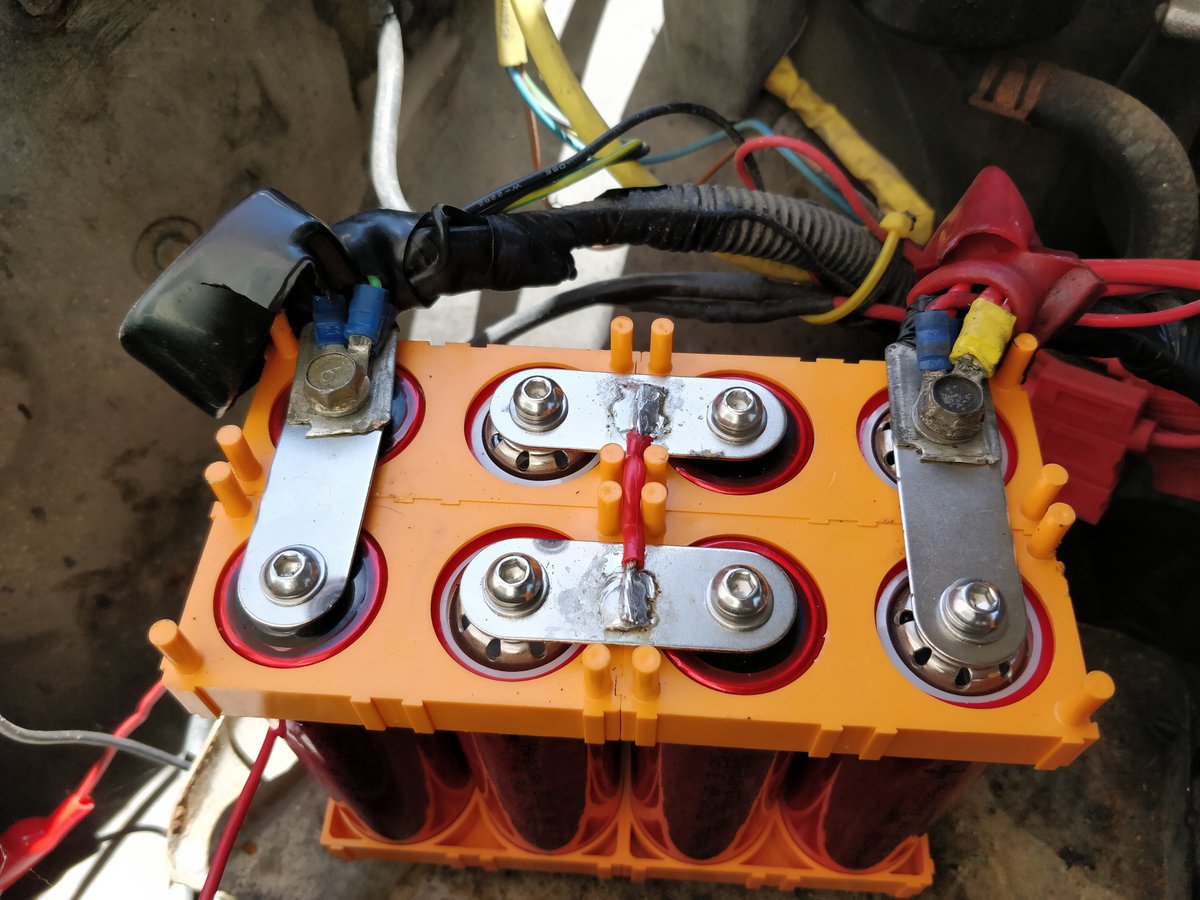

- 4 cells / 8AH for 1.6l or smaller engines

- 8 cells / 16AH for most of my cars (datalog from FreeEMS on 16v Volvo 240 showed excess drop while starting on 4 cells, but it did start, just a bit lazily - this is worst case with an old style inefficient starter)

- In-firewall isolator switch to totally turn the car off except for:

- different cells and larger capacity for Stagea to keep trip counter memory... grrrr

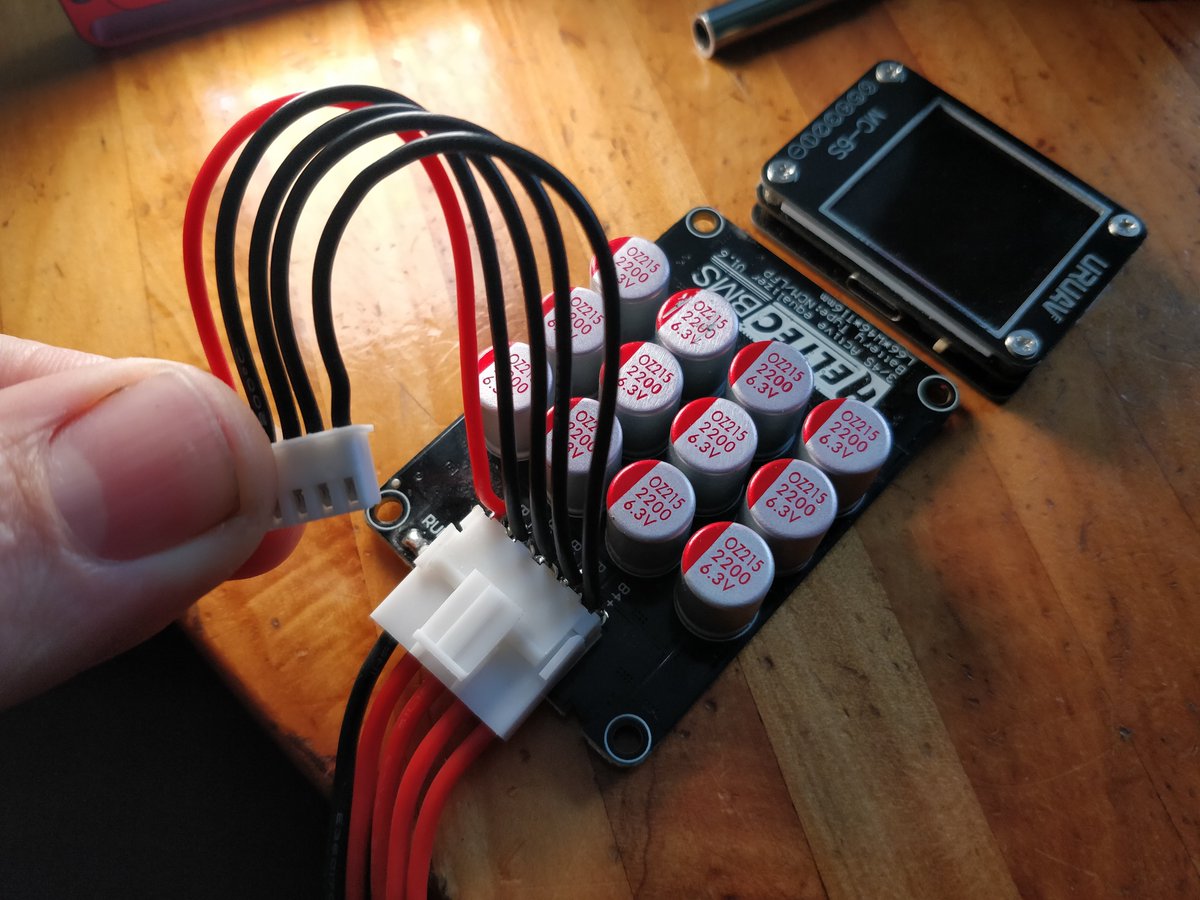

- 1A capable HeltecBMS brand 4S capacitor balance boards, small, cheap, efficient, low current drain (rated to 6A but cannot control a set of cells to 14.6V at 6A charge, first to fill goes over voltage badly

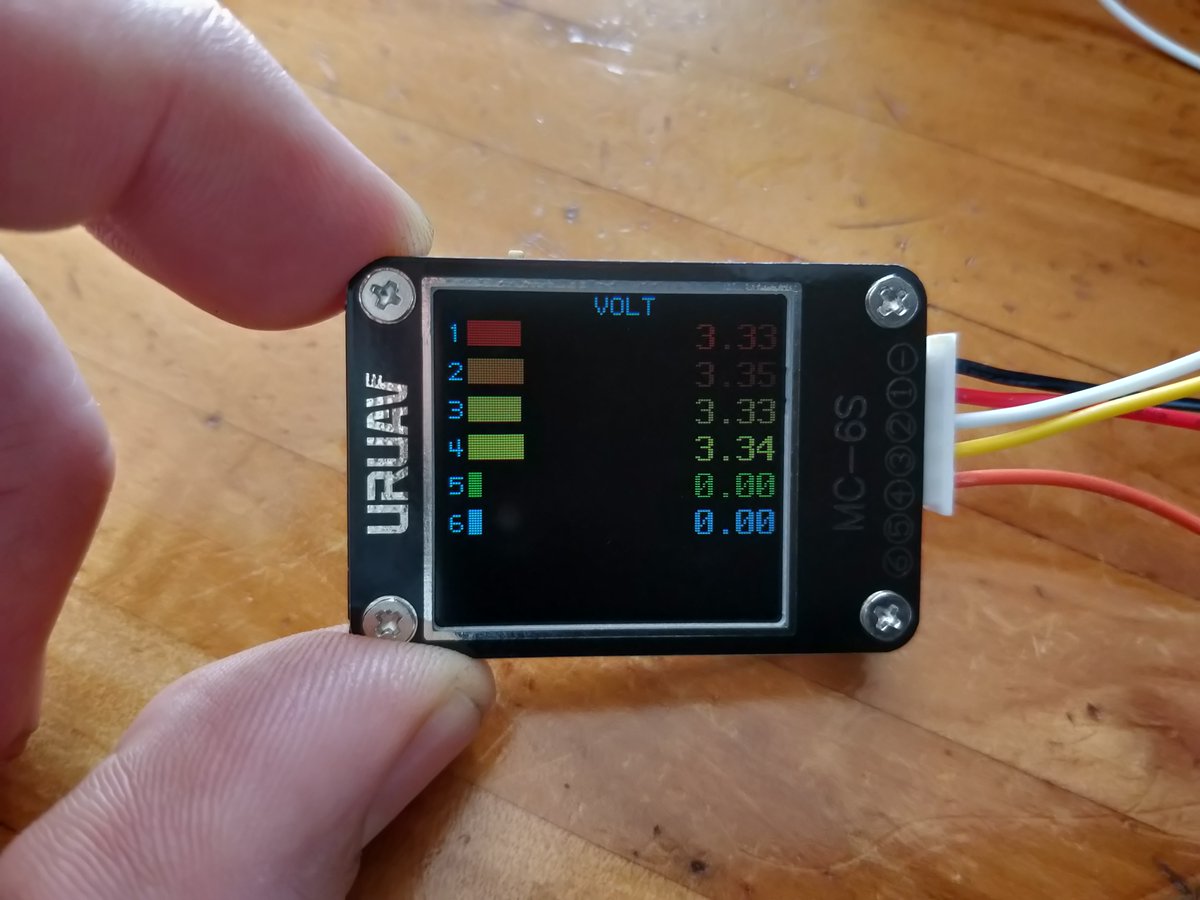

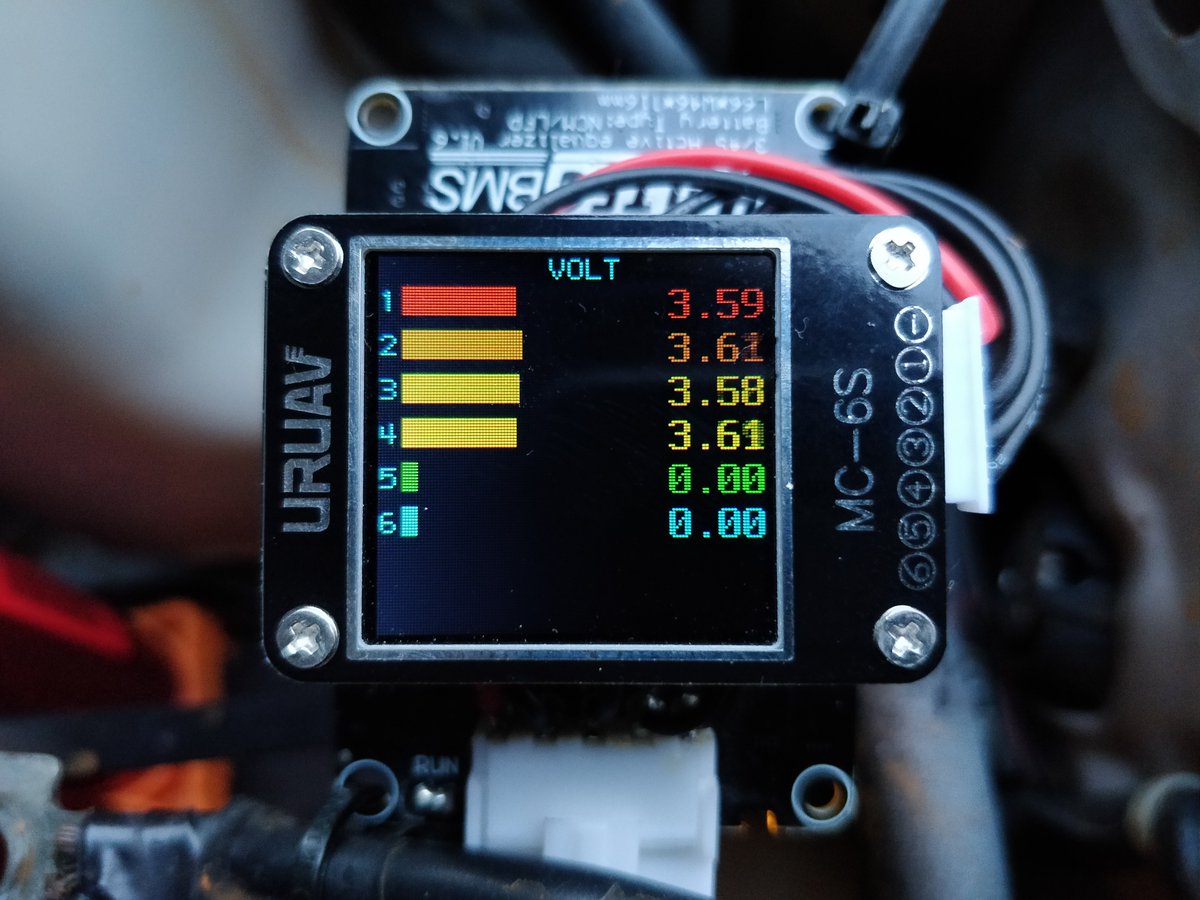

- URUAV MC-6S colour LCD cell voltage display, again low current draw

- 4PST switches for URUAV and balance board to totally disconnect the battery when not in use = 10+ years and you can show up, switch it on, spray some ether and start the car, awesome

BMS for these things capable of running a starter motor are exceptionally expensive and not really needed except for under voltage cut off which I'm handling with the isolator anyway except Stagea which I'll just over-provision so it can't run flat from leak current quickly enough to fail.

But alternator current really needs handling for best longevity. Three parallel approaches:

- little 1A/6A capacitor balance board to maintain micro balance

- Precision medium current 3.65V clamp using precision V ref and grunty darlington or FET - stops cell over voltage during charging

- High-current zero drop FET diode for discharge to starter/vehicle with parallel resistor chosen to appropriately limit charging current (this will take some experimentation and I can do that now using a jump pack to start the car, a resistor and current shunt in series to measure charge current, and a near-flat LiFePO4 pack in the car to provide load to the alternator FET rating would need to be about 300-350A per 8A 300+CCA capacity

For solar or boat use I'd do things a bit differently. Like the Stagea I'd over provision capacity even though I have started the 8 litre cummins with my 8AH LiFePO4 prismatic based jump pack (just!) and could almost certainly start it with 8 cells and start it pretty well with 12 cells. If for any reason extended cranking was needed to get the thing running, or multiple start/stop sequences during problem diagnostics, having more capacity would be a winner for sure. On the house side of the boat or for solar I'd use a traditional BMS that could balance, and isolate for under/over Voltage as necessary, or perhaps in the boat just an alarm on the low side and similar to the cars on the high side.

Given how much lighter these things are for the same capacity it's also possible to move them up higher in the boat so they're safe from water should she be sinking or leaking and splashing. Salt film discharge ruining expensive cells would be a very sad thing to have happen. Can also put them closer to where they're needed, and/or put some super capacitor banks at high draw locations to smooth the flow (winch, starter, pumps (maybe)).

I guess I should throw some media in here for you, one moment...

I should add that they ARE dangerous, but only in combination of:

1. How light they are - carry with one hand and other objects...

2. How exposed all the terminals are...

3. How much current they can dump out into your keys or other objects...

Yes, don't ask me how I know, but I did burn myself picking up the keys afterward :-D

Any comments welcome in this thread. No one uses forums anyway, so this is a diary/monologue ;-)