The last couple weeks I've put in an enormous amount of time into disassembling the Toxic Taco's A43D transmission subcomponents, cleaning them, and rebuilding them with new seals, gaskets, clutches & frictions discs, and evaluating what needs to be replaced due to severe fatigue. In some ways the process has been immensely cathartic and I've had lots of Car Talk, AGCO Automotive Hour, Car Craft, Hot Rod Magazine Live, and Rod & Custom Radio podcasts to keep me company. The rebuild has also allowed me to meet some business owners and technicians in the area who have had colorful histories in the local drag racing scene.

For those interested, here are a handful of photos taken from hundreds that more fully document the entire process:

^ This is the Aisen A43D automatic transmission from my Toyota Tacoma. There are many like it, but this one is mine.

^ Here's my kitchen/transmission workshop where the magic happens. I don't cook much, but when I do...it involves an impact wrench and lots of Q-Tips.

^ All small parts are kept in labeled zip-loc bags and sorted by steps to match a repair manual.

^ These are parts to be discarded at some point.

^ Notice the shattered gear in the left half of the front pump. You might also notice the imprint it seared into the right half. After 120k miles, you can also see how caked on the transmission fluid is in the surrounding channels. The gloppiness of the transmission fluid's been consistent throughout the entire unit and has made cleaning immensely difficult. Everything had to be cleaned thoroughly since metal fragments made their way out of this pump and into other areas of the transmission.

]

]

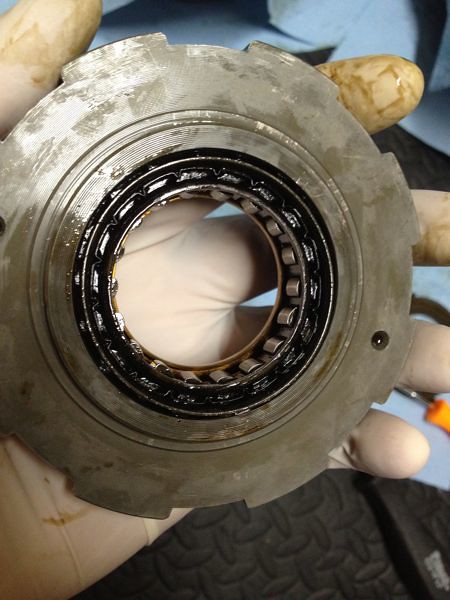

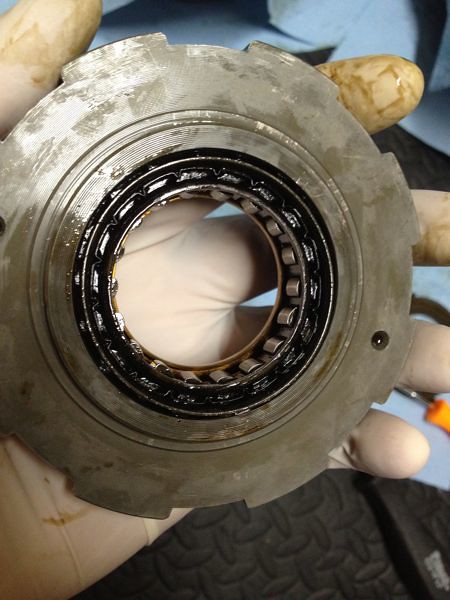

^ This one-way sprag fit around the sun gear assembly. At some point during the transmission failure, it turned into a two-way sprag. If you look closely, you can see how the inner and outer bands have turned out of alignment and caused most of the knuckles to depress.

^ You can see some charring and bowing here of the Number 1 Brake flange and lower friction plates/discs. Both the top flange and snap ring had to be replaced.

^ This is how the case came out after a good cleaning and paintjob. Most of this will get marred up during reinstallation, but I approached the rebuild with a certain amount of pride and want everything looking top notch before reinsallation.

^ To get the truck running temporarily, I masked off parts of the painted bellhousing and reinstalled it so the starter could be situated. After months of neglecting this rebuild, it was nice hearing everything fire up.

^ Though the brownish transmission fluid looks glossy, it's fairly gloppy and clogging up the valvebody.

^ For comparison to the earlier valvebody image, here's a cleaned component.

This is about a week away from reinstallation in the vehicle. Hoping for the best.

-Jeff

]

]