There is text in the picture that explains most stuff that one needs to know when doing an upgrade like this.

Obviously the hoses and hard lines to and from various components should be sized according to the flow through them to ensure no restriction to the flow occurs.

It's important to realise a few things.

When the engine is stopped or idling, the entire volume of the main "to rail" pump is flowing through the regulator and back to the tank. thus the return line needs to be sized such that the full flow of the pump doesnt generate more pressure by restriction than the regulator is trying to achieve. the main line should be sized to drop no pressure at the full flow of the pump. the less pressure dropped across the main line, the less hard the pump has to work to produce the final pressure at the rail.

If for example your main line fwd was so small as to drop 15psi at the full flow of the main pump, and you wanted a base pressure of 50psi, and a boost pressure of 25psi, the total that the pump sees is 90psi. thats hard work, and a walbro might well pack up and go home if it has to work under those conditions very much. if on the other hand you have no restriction going fwd, your pump will only be pusing 75psi, much much easier for it.

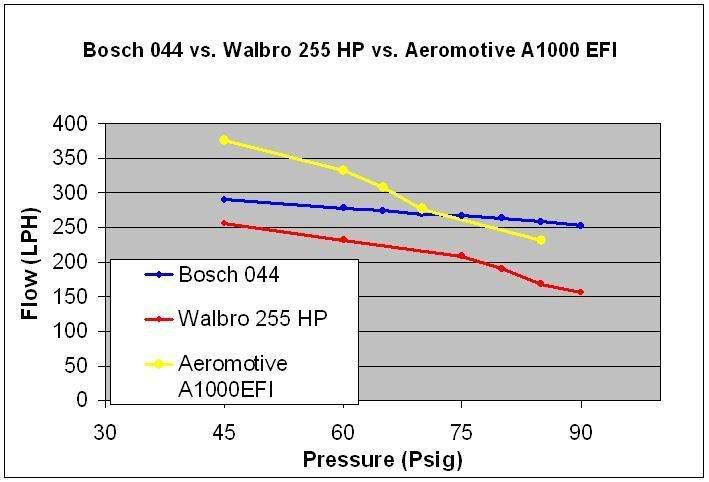

When testing my fuel pump setup i had the return from the reg plumbed out through a hole in the front panel into a bucket, and had the regulator wide open. i turned the system on, and with the hose squirting fuel horizontally increased the rail pressure more and more until i got to 110psi. then i chickened out. my 044 pump did not reduce its output at all from no psi to that level. and that is why i chose it. under the same conditions, the walbros flow has been significantly reduced by the time high pressures like 80 or 90 are reached. the walbros ratings are not at a high load, and as such will make the hp that they claim on a naturally aspirated engine, but will struggle to do the same without leaning out on a high boost application.

A 2 litre surge tank will supply a 400hp engine for about a minute.

Narrow and tall are ideal. I would want it at least twice as high as it is wide.

The fuel filter can go anywhere you like. For maximum protection and safety, I would(and did) place it between the tank and lift pump such that A all fuel is cleaned before seeing a pump, B main pump flow is totally unrestricted. In order for it to work well on the suction side, you need a large filter. I could not find a decent filter for cars, so I went with a marine screw on job.

Errata :

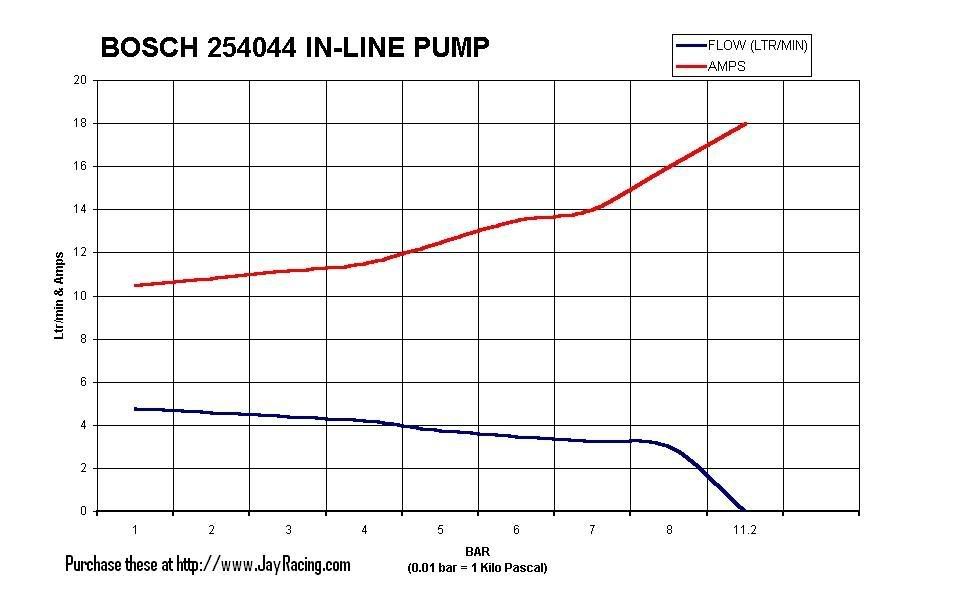

Bosch 044 flow vs. pressure :

Bosch 044 vs. Walbro HP 255 vs. Aeromotive :

(spot the pump intended for NA use...)

My implementation :

Fred.