Now, thinking about the flange and the vice and supporting the piece of 20mm plate that it bolts to securely and stiffly I decided that I should run a couple of thick deep sections across the fasteners in the top plate, and stepping up into the table if there is any (due to balance point), and then to the bottom of the 20mm and bolting securely to that, too.

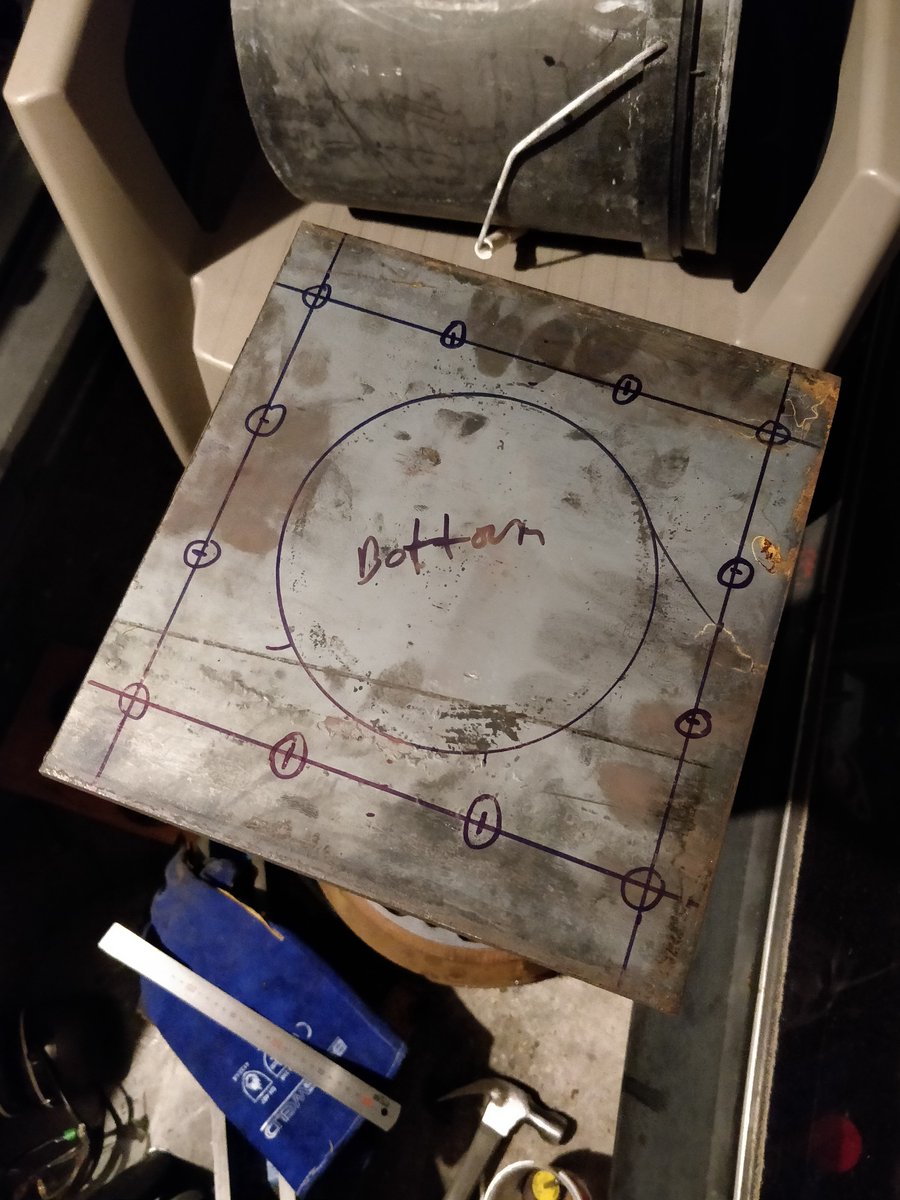

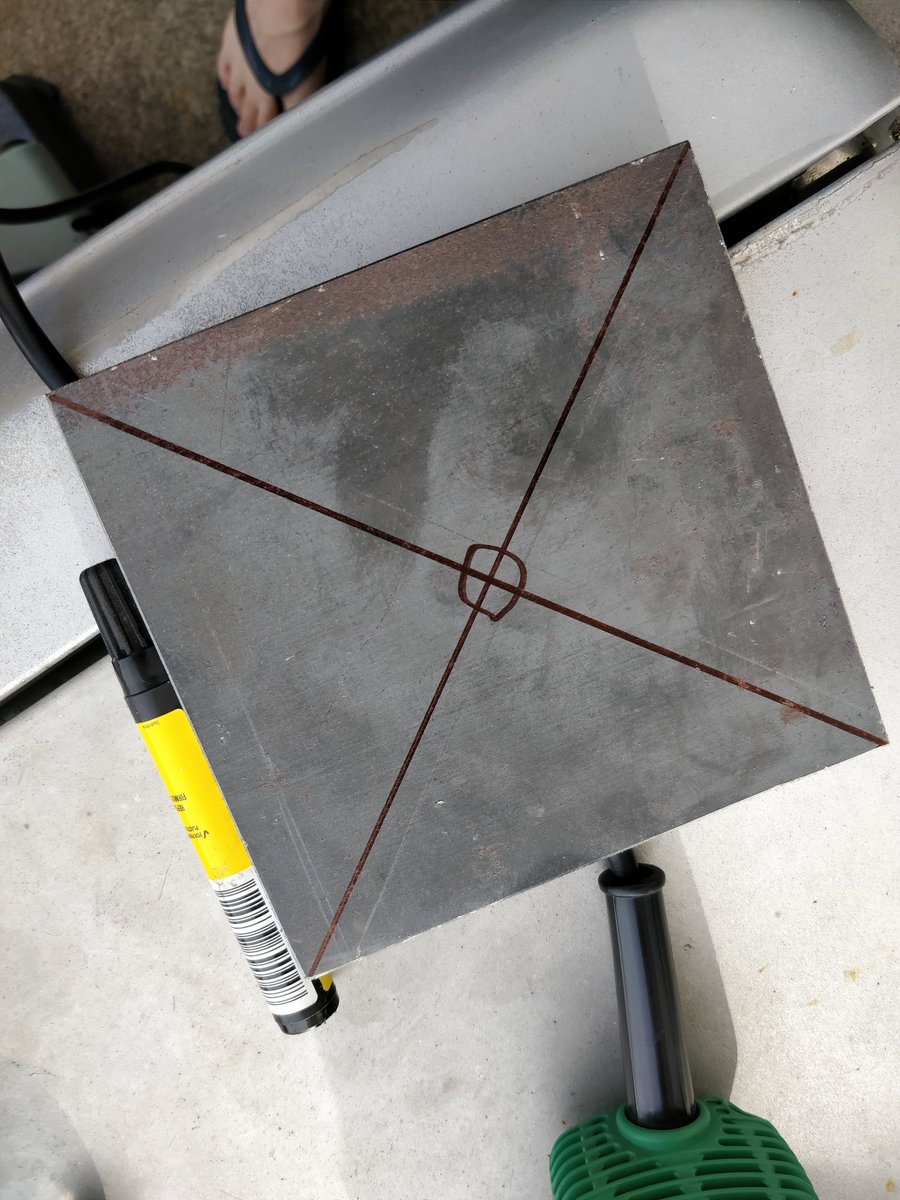

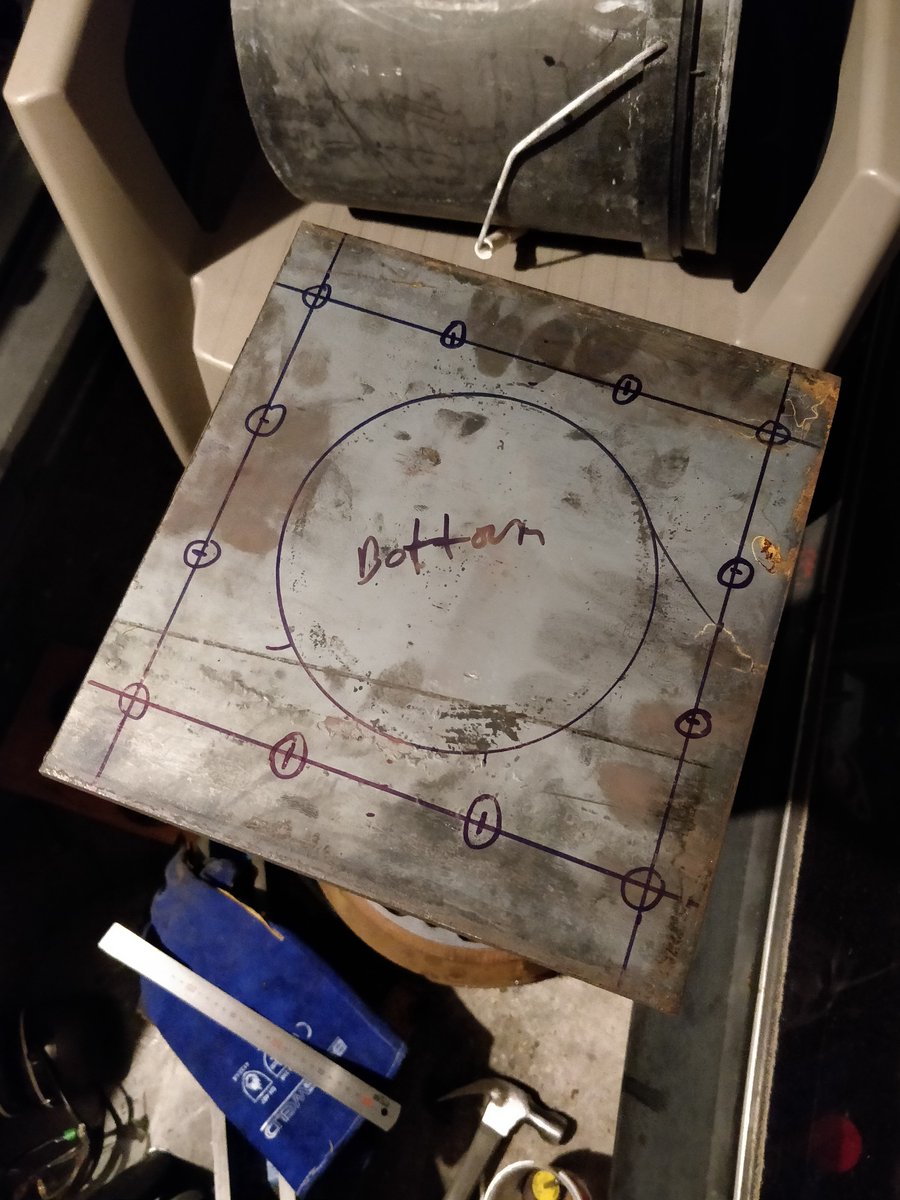

Roughly marked out (inlined below):

https://twitter.com/FredCookeNZ/status/ ... 3395694592

50mm thick table, plus 16mm thick plate, minus 20mm thick plate, equals 46mm step up from fastening surface one to fastening surface two. The remainder of the piece needs to be amply stiff, so minimum width is 100mm. Thus options are:

100x20

100x25

130x20

130x25

Or something smaller and spacers instead of cutting to make the step up. But that would look messy/cheap/untidy/sloppy to me.

100 gives us 54mm of meat remaining and 130 gives us a nice 84mm of meat.

20 requires M10 (5/side) or M12 (4/side) and new taps as I don't feel the 3mm per side that M14 would leave is enough meat left over.

25 with M14 would leave 5.5mm per side which is ample. M12 would yield 6.5 per side which might be even better. M10 7.5 per side which feels excessive.

M14 washers are about 30mm which would look silly even on 25mm stock. Presumably M12 are at most 28mm, likely 26 or so, which would look mint on 25mm stock.

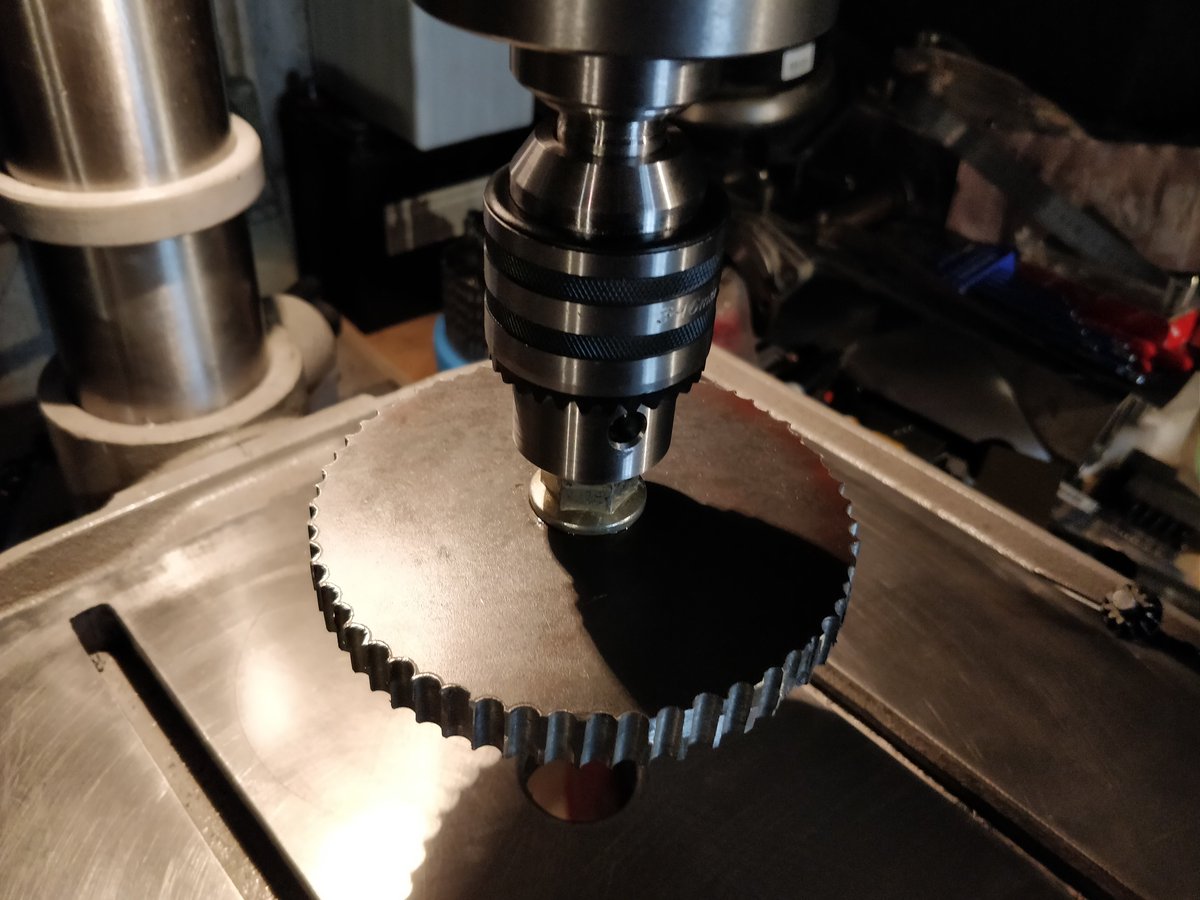

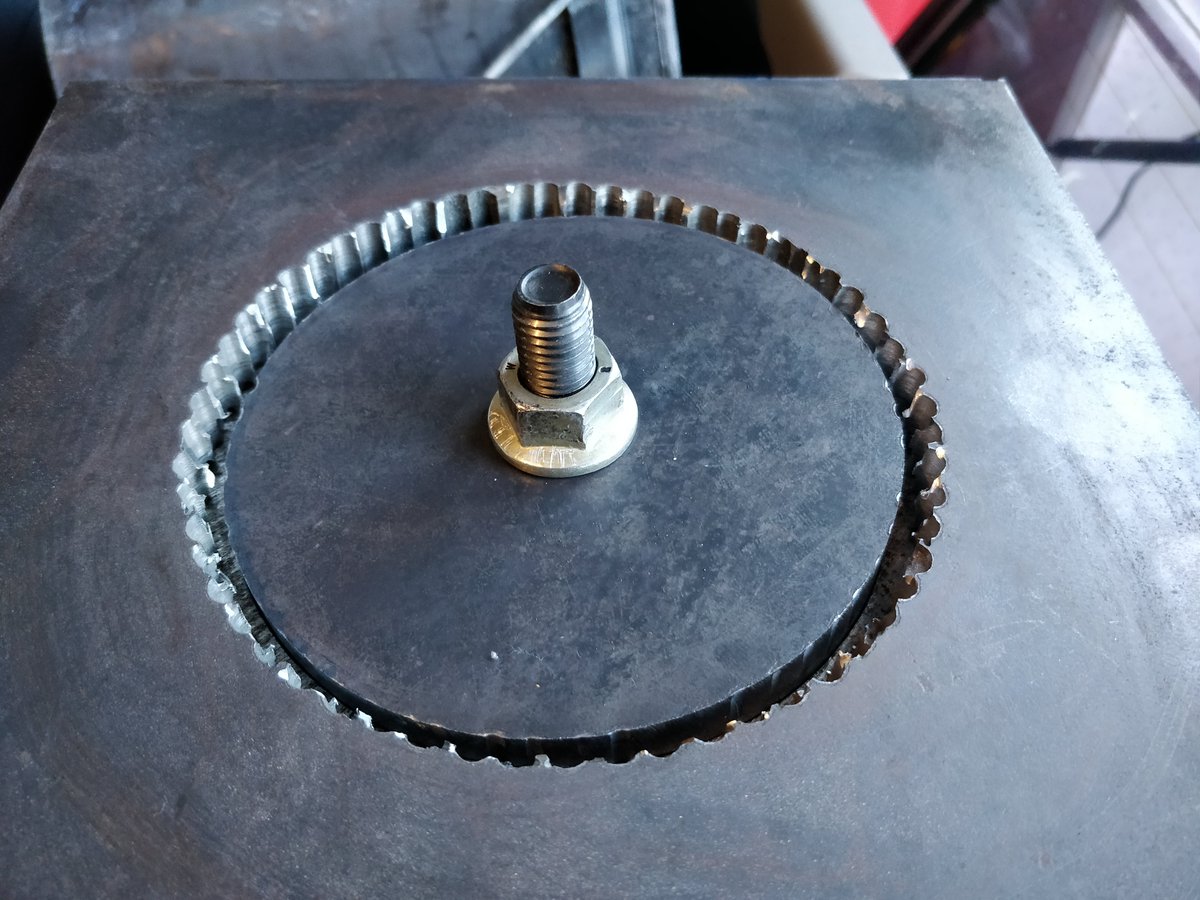

I think I might pull in a favour and get the exact heights dialled in by way of a milling machine. Will give me nice flats for the fasteners and table surfaces alike.

Centre of gravity calculations.

50x450dia steel weighs in cm (7.85 * PI * (45 / 2)^2 * 5) / 1000 = 62.42 kg or a little less, centred on itself

200x220x20 steel weighs in cm (7.85 * 2 * 22 * 20) / 1000 = 6.9 kg

vice weighs 32kg

vice plus plate = ~39kg centred on the plate.

Datum = edge of table

Units = cm and kg

Moment of table = 62kg * 22.5 = 1395

Moment of vice/plate = 39kg * (45 + 11 = 56cm) = 2184

Total moment = 3579

Distance from edge of table to CG = 3579 / 101 = 35cm, 350mm, 100mm from the other edge of the table.

IE, with the top plate hard up against one edge of the table, it'll still be vice-heavy, especially adding in the ignored under-brace weights.

But given the base is about 400mm wide, and substantially heavy, it won't be a problem stability wise. Excellent.